- Email industries@raysonsgroup.com

- Shell Moulded Castings Manufacturers India

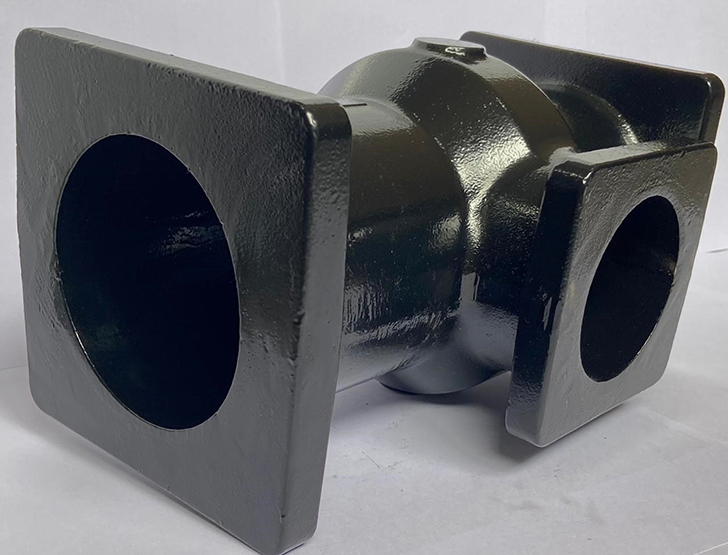

Shell Moulded Casting Foundry in India

Industries we serve for shell cast :- Automobile industry, Hydraulic, machine tool, Oil and Gas, Agriculture

Our state-of-the-art shell mould cast set up helps us deliver precise, durable castings that require low production time, and are highly cost-effective. Shell mould casting is steadily replacing the traditional investment cast because of its dramatically lesser costs and shorter lead time. Moreover, due to the absence of moisture in the shell, the resin binder on the shell surface burns out, making shaking out castings easy.

Our shell mould unit is capable of manufacturing any component shapes our clients requires, with weight ranging from 1kg to 40kg. We have garnered a vast clientele made up of leaders from several industries including machine parts manufacturing (OEM), automotive, hydraulic and more.

Some of the salient features of our shell mould casting foundry are

- Modern machinery and skilled personnel that ensure precise measurement, shapes and quality as per requirement.

- Excellent surface finish and machine accuracy which cater to the low tolerance band, further reducing machining and overall production cost.

- Production of even extremely complex shapes with fine detail and accuracy.

- Several material options to best suit the purpose of the component.

With our innovative approach, we stay ahead of the curve, delivering the most efficient solutions to our clients.

Raysons Shell Cast Competency

Casting Range Weight

No Bake Castings : up to 1000 kg. (Future Expansion)

Infrastructure

Reviews

"We’ve been using gas valve components from Rayson Group for over 3 years, and the quality has always exceeded our expectations. The precision and strength of the castings have been crucial for our projects, especially in the Oil and Gas sector. Highly recommended for anyone looking for reliable castings!"

"The team at Rayson Group is incredibly responsive and professional. From the initial inquiry to the final delivery, they kept us informed every step of the way. Their technical support was instrumental in helping us find the right resin coated sand for our process. We couldn’t be happier with the service!"

"We required customized castings for a very specific application, and Rayson Group delivered exactly what we needed. Their team worked closely with us to understand our requirements and provided a tailored solution that fit perfectly with our project’s needs."

"We’ve been working with Rayson Group for several years now, and they’ve been a reliable partner throughout. Their products consistently meet our high standards, and we’ve built a strong relationship based on trust and quality. We look forward to continuing our partnership."

"The technical expertise at Rayson Group is top-notch. Their team helped us optimize our casting process, saving us time and reducing material waste. The quality of their SG iron castings is exceptional, and we highly recommend their castings."

Frequently Asked Questions

Raysons Group specializes in the manufacturing of high-quality shell moulded castings, including cast iron and SG iron castings. Our products are used in a variety of applications across multiple industries.

Our castings are used in a wide range of industries, including Automobile industry, Hydraulic, machine tool, Oil and Gas, Agriculture. We provide customized solutions to meet the specific needs of each sector.

The minimum order quantity varies depending on the type and complexity of the casting.

At Rayson Group, quality is our top priority. We implement rigorous quality control processes at every stage of production, including material inspection, dimensional checks, and non-destructive testing. Our quality management system is certified to ISO 9001:2015 standards.

Lead times vary based on the complexity and quantity of the order. Generally, production takes between 2 to 4 weeks.

We use high-grade cast iron and SG (spheroidal graphite) iron for our castings. These materials are selected for their superior strength, durability, and performance in demanding applications.